Thermal performance for CellTank and CellReactor

Traditional thermal control of glass STR is by wrapping a flexible heating blanket around.

Most often thermal control is designed with PID control either relay or proportional control for max 40° liquid media temperature. As to the delay over the many barriers from heating blanket to thermo couple we see heating blanket reach +80°C – which is NOT recommended for Single-Use products.

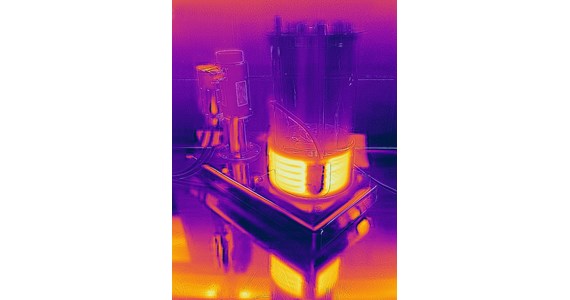

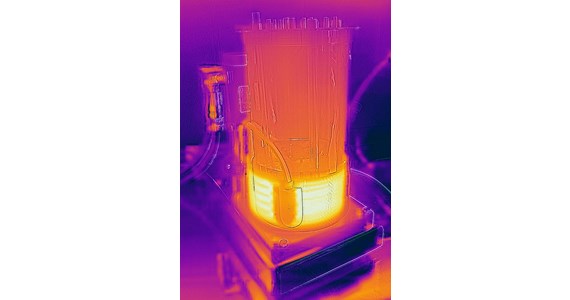

Left – CellTank wrapped with 75x350 mm blanket. Tested setup with 75 x 350 mm heating blanket on 3200 ml vessel with 1.400 ml media and 200 RPM. Photo to the right shows even yellow colour in media.

In reality the typical setup involves

- a vessel, container with a polymeric wall surrounding a media volume

- the volume filled to some extent with media = thermal mass, thermal conductivity, mixing performance

- the thermocouple arranged inside the media = thermal delay

- the thermo couple arranged inside a polymeric tube = thermal delay, air gap

- air gap between heating blanket and vessel wall = thermal delay

- the thermal energy supplying device outside the vessel = vessel wall thermal conductivity

- a Process-Control-System with some kind of PID regulating mechanisms and conditions

This complicated setup is NOT stable or error free!

General precaution and improvements

- there must be a direct thermal connection between supply and measuring device

- thermal supply to be avoided on an empty vessel = vessel damage

- Insure appropriate cooling of heating blanket from the inner side of the vessel by the media!

- Improve performance, reduce SUB media gradient by wrapping insulation layer around the blanket and vessel. A sheet of bubble plastic foil is great

- Don’t arrange your bioreactor under an air-condition outlet

We recommended tightening torque is 10-20 Nm supplied by the one or more springs.