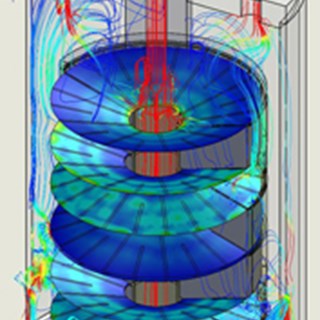

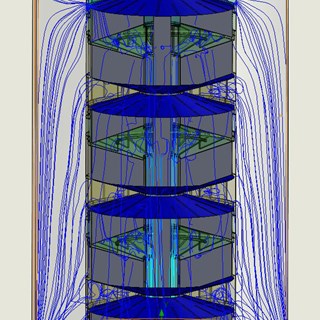

Fluid dynamics inside the CellCore body

CellCore require a pump for internal media re-circulation.

Centrifugal pump integrated in CellTank-34

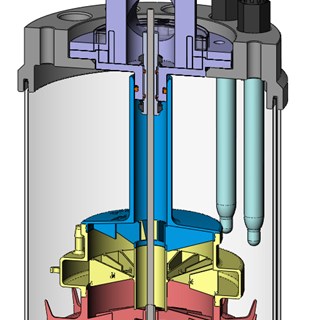

CellTank-34 in-corporate a centrifugal pump impeller able to deliver up to 1,000 mm WC pressure. The pump creates easily the desired velocities (0-25 cm/min) across the scaffold/matrix.

The impeller is equipped with 4 pcs. each 3100 Gauss magnets oriented with 90° in between. High performance Magnetic-Stirrer-Tables (MST from ProlifeCell) are able to transfer the power required for ultimate cell densities. The potential traction loss should be tested in each particular set-up.

Its highly important to locate the bioreactor accurate (x, y coordinates) with the impeller centre over the Magnetic-Stirrer-Table centre. Check out the perfect MST here including the SUB-Support-Square (SSS). As to mechanical limits max revolution should not exceed 1,000 rpm. Required delivered power from the MST will exceed 25 watt at 650 rpm. Servo motor should be able to deliver >50 watt rated power at 650 RPM.

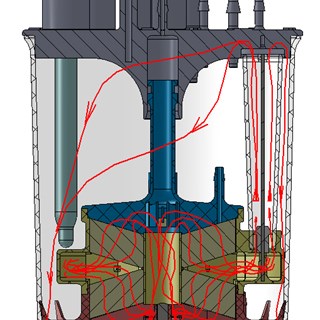

Membrane pump integrated in CellTank-35 and CellReactor-36

CellTank-35 and CellReactor-36 integrate the Clio diaphragm pump for internal media re-circulation. The diaphragm pump creates easily the desired velocities and shear forces across the matrix. Drive Unit available from ProlifeCell.

The integrated diaphragm Single-Use-Pump facilitate a medical grade silicone membrane wetted on one side. The diaphragm being a parts of the CP-SUB solving various tasks; 1. inoculation; 2. re-circulation; 3. cell bleeding.

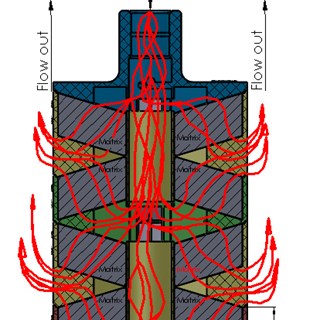

- Low velocity for trapping cell´s inside the scaffold pores during seeding

- Continuous re-circulation serves the purpose of feeding the cells

- Sequentially increased shear force for controlled cell removal for bio-mass control